PROJECTS

PROJECT TYPE

Functional analysis

Improve overall and operating performance

Increase production equipment efficiency

Process automation

SCADA programming

CLIENT

Pellet Plant

SECTOR

Agricultural

REGION

Eastern Township

The client

We took part in several projects with this company, which specializes in the production of fertilizer pellets. Its low-emission, energy-efficient products make this plant a great example in terms of sustainable development.

Mandate

Lem was asked to automate the plant’s monitoring and control systems, which were still manual and therefore increased the risks associated with human error.

Challenge

The main challenge of this project was the necessity to add new production equipment without having to increase the number of operators, which required a thought-out and effective automation solution. This project was successful in providing the following solutions and services.

Solutions

- Creating configurable, flexible production processes and automating routing for each type of products

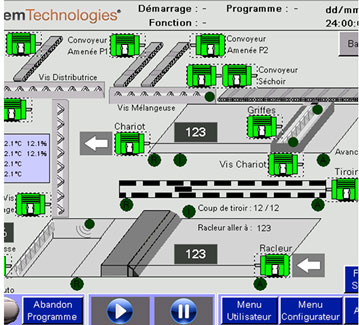

- Implementing a SCADA production monitoring system that would measure output for each type of products

- Creating a command station in each production sector of the factory, including a touch screen and animated controls to monitor equipment and processes as well as facilitate the work of operators

- Setting up a wireless interactive dosing system to allow the operator to view and control the weight of each raw material added to the mixer

- Allowing historical archiving of all alarms generated during a shift

- Automating the flow of product to the press in order to maximize equipment efficiency

- Providing remote technical support to diagnose problems and allow changes or additions to the PLC program and operator interfaces (HMI)

Benefits

- A reliable, structured, versatile and user-friendly system

- Automation that eliminates human error and associated losses

- Production shutdowns are virtually eliminated

- Traceability of product types for each shift

- 15% productivity gain after only 6 months

- Quick and efficient remote support

- Estimated efficiency gain: + $75,000/year